The Art of Reinvention: Turning Waste Into New Materials

By Mimi Tiu

July 02, 2022

Long before sustainability became a buzzword, Pedro “Pete” H. Delantar Jr. and his wife, Catherine V. Delantar, were already practicing sustainable efforts through their Cebu-based manufacturing business. The CEO and co-founder of Nature’s Legacy Eximport, Inc. recalls, “Sustainability has always been in our hearts and minds. When we started in 1986, we were producing rattan furniture, bamboo gift baskets, Mactan coral stone, and more. The mindset was always to conserve, minimize waste, [and] maximize utilization and extension of life of the material. It was intentional as we saw that raw materials were becoming scarce and [were] wasted in manufacturing.”

“There [was] no Life Cycle Assessment in those days,” he adds. “In the design stage of a product, all aspects should be considered beforehand. Raw materials should [be utilized] to the fullest by creating another product.” This is coincidentally how their subsidiary company, Floreia, came about in 2013. They decided to make use of the excess lengths, off cuts, and waste they already had from their factory and transform them into fashion accessories and decorative pieces for the home.

FINDING GOLD IN WASTE

As the couple expanded their business, they invested in a property that was piled with branches, twigs, and tree barks. Instead of collecting and burning these as firewood, the agroforest debris sparked an idea that resulted in many of their signature innovations: The concept of recycling raw materials into something new.

The process was long and arduous with some inventions taking years to develop and patent, but the pair was up for the challenge. Delantar shares their winning formula, with science and curiosity working hand in hand. “Science is where process, composition, and skill are combined. Curiosity [is] applying all possibilities—challenging the limits and probabilities the material can and can’t do.”

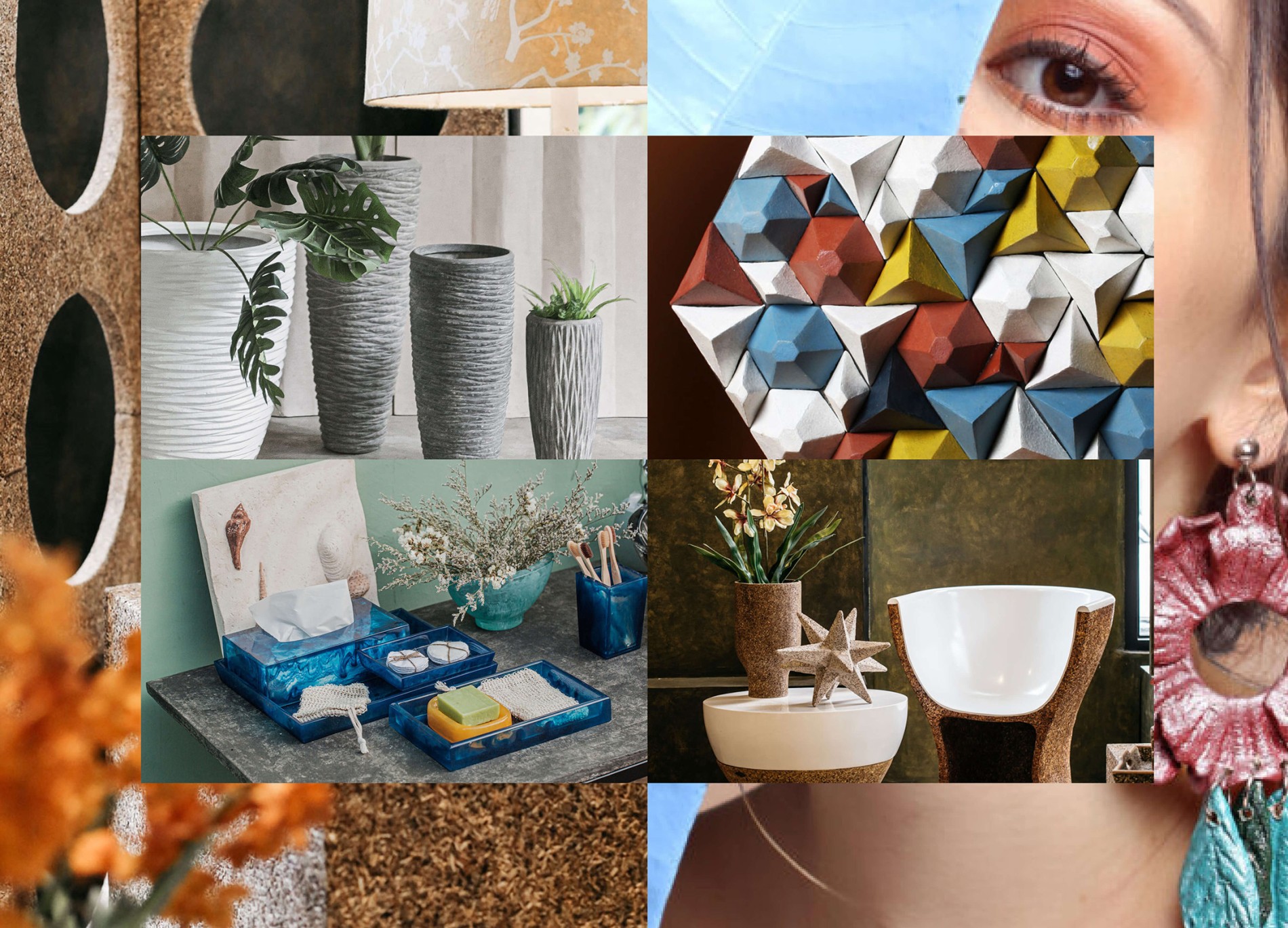

From years of continuous research and experimentation, Nature’s Legacy has brought forth four uniquely patented materials out of resources most people would simply disregard: Stonecast, Naturescast, Nucast, and Marmorcast. Despite being recycled or upcycled, each reimagined material manages to retain its raw and natural characteristics as it is fashioned into a distinct piece.

MATERIAL INNOVATIONS

Stonecast is made by upcycling natural crushed limestone and dry stamping it into a mold by hand. The mixing process is comparable to cast cement and cast plaster, but the co-founder reveals that’s where the similarities end. “We first patented Stonecast because of the new teaching, new composition, and new process,” says Delantar. “Our innovation focuses on the composition and process. We implemented additional science and steps into it, thus simulating the real look of limestone and coral stone.”

He adds, “Stonecast is applicable in almost any surface application and is not so expensive to process.” The versatile material has a wide range of uses—from home furnishings and lighting fixtures to packaging such as trays and gift boxes—and functions for either indoor or outdoor installations.

Naturescast makes use of recycled wood and non-timber forest debris—similar to the refuse the Delantars found on their property. Since these organic materials are bound by water-based binders, the resulting innovation is completely biodegradable and recyclable. Exhibiting a cork-like texture, the fully customizable material works well as indoor furniture (tables, chairs, and lamp shades) and decors (wall art, bowls, and planters).

Similar to Naturescast, Nucast material does not contain Volatile Organic Compounds (VOCs), which may cause harmful effects to its makers. Delantar explains, “VOCs normally come from off-gassing. These are gases or chemicals that are released from the product. For example, paint and fake leather emit smells and gasses that hurt the eyes and respiratory system. [These are not present] in Naturescast and Nucast.”

Instead of using agroforest debris, Nucast employs recycled paper composite to mimic stone and metal textures. The upside to using this eco-friendly invention is its durable yet lightweight quality, making it 100 times lighter than traditional finite materials. Delantar reveals that since 2014, Nature’s Legacy has upcycled over 1.08 US Tons of recycled paper to produce this flexible composite. “[The amount may not seem like] much, but if [the recycled paper is] placed in loose storage (dry and shredded), the volume for one ton is a lot as it has a lot of air.”

Marmorcast is crafted by hand by combining high-grade cast polymer with polyester resin. From frosted wall partitions to glossy tabletop decors, the mirror-like finish of this material lends an air of class to any setting. Unlike the first three innovations, Marmorcast does not use sustainable materials. Nevertheless, Delantar shares that “the manufacturing process adopts the Sustainable Consumption and Production (SCP) philosophy. [It means that there is] almost no waste, [it] uses only what is needed to produce a product, and [it is] designed well to utilize the resources to the max.” Additionally, this innovation is made through the “clean production method.” It typically involves the conservation of raw materials as well as the absence or reduction of toxic components and emissions during production.

There are no size or color restrictions as to how Stonecast, Naturescast, Nucast, and Marmorcast materials can be used. The creation process begins from an idea, then moves on to “sketching and designing, model and mold making, prototyping, [then] sampling and dry run.” “A product [can take] months to do before [you can see] an actual piece. It can be revised or extended to a new product by changing [its] colors and adding accents,” shares Delantar.

THE LOWDOWN ON SUSTAINABILITY

With over 35 intellectual properties under their name (and many more in the works!), Nature’s Legacy continues with their quest to find raw materials that can be rehashed into something new. “Materials [are considered] important resources in our company. It’s the strength of our manufacturing business… We source our raw materials by understanding [its] availability. If a raw material is not readily available and accessible, we [do not] even consider using it. So we never have problems with raw materials,” says Delantar.

But more than just finding readily available and accessible natural resources, sustainability plays a big factor in how the company intrinsically works. “We aim to have a positive impact on the environment and the community by serving as a platform for sustainable living. We do everything with sustainability in mind,” he explains.

Sustainability can be achieved in a variety of ways. The CEO of Nature’s Legacy goes into detail about the difference between sustainable materials, sustainable products, as well as sustainably made items. “A material is considered sustainable [if it is] available over time. Meaning, it regenerates by itself [and] grows without care. Sustainable products [are] products made of rapidly renewable materials like bamboo, seagrass, Cogon grass, shrubs, and fast growing trees like Acacia mangium. [These products are also] manufactured [using] less carbon dioxide, causing less environmental impact.”

Sustainably made, on the other hand, goes beyond the product’s raw material. It entails processes and technologies used in its creation. Delantar reveals it can be something “made from a sustainable resource [such as an upcycled material] using very minimal energy, minimal waste, or less logistics requirement. [It can also use] renewable energy, or a percentage of its power comes from non-grid generation.”

Nature’s Legacy ticks all the boxes by developing sustainable materials and employing sustainable processes to manufacture their goods while producing as little waste as possible. “The keyword to sustainability is resource efficiency,” shares Delantar. “Our innovative materials help the sustainability efforts in many ways, and also establishes an impact to the world that resources should be upcycled and reused or repurposed. Full appreciation of the idea and creativity of [our] invention Naturescast should be an example of simple and effective practices in sustainability.”

BUILDING A SUSTAINABLE FUTURE

Both Nature’s Legacy as well as its subsidiary Floreia are B Corporation-certified sustainable manufacturing companies. They set their goals by aligning with the 17 Sustainable Development Goals (SDG) created by the United Nations, which include responsible consumption and production, decent work and economic growth, and sustainable cities and communities.

“Nature’s Legacy was born [out of] our commitment to nature and [the] use of nature’s bounty, and [our] environmental commitment to sustainability,” says Delantar. With that pledge, the company has adapted a 360° Sustainability ethos that goes beyond manufacturing sustainable materials and products. It also involves providing holistic guidance, recreational outdoor spaces, and affordable housing units for its artisans. Thanks to the close proximity of its workplace, carbon footprint is diminished through carpooling and decrease in transportation use.

Meanwhile, Floreia’s sustainable “circle of life” system minimizes waste impact on the environment and provides livelihood opportunities and skills development for its workers. Named after the couple’s mothers (Florencia and Victoria), the brand takes advantage of Naturescast and Nucast excess materials from the Nature’s Legacy factory. Stay-at-home mothers from hard-to-reach mountainous areas are hired to create decorative home and fashion pieces. These handmade works are then dried with the help of natural air and sunlight, resulting in minimal carbon footprint.

Over the years, the company’s sustainability efforts have not gone unnoticed. Nature’s Legacy received the Golden Shell Award for Excellence in Design and Manufacturing at Malacañang Palace in 2004, while their Naturescast innovation garnered the 2015 Gold Invention Award in Geneva, Switzerland. Despite the recognition and awards they’ve received, Delantar feels like the company still has many lofty goals to achieve. Aside from having more inventions, utility models, and designs patented, he dreams of “[moving] up to more technology that can enhance production and processes as we cannot always be semi handmade and semi mechanized. We are also in talks with possible global partners that are aligned with SDG.”

Looking at the bigger picture, the manufacturer and innovator also hopes for more people to champion the cause for sustainability in the country. “We have a lot of potential. As a country, [maybe we can have a] single platform or program that really encourages individuals, businesses, [and] industry organizations to implement [sustainable ways]. Like a simple policy on how to spend developments or renovations in the local levels by buying locally made, [high-quality] products that adhere to sustainable practices.”