Social Design

By Patti Sunio

March 28, 2022

With the vision to encourage micro, small, and medium enterprises (MSMEs) toward innovating their materials and finished products through more thoughtful, eco-conscious processes, CITEM has recently initiated its Sustainability in Manufacturing and Product Development Program.

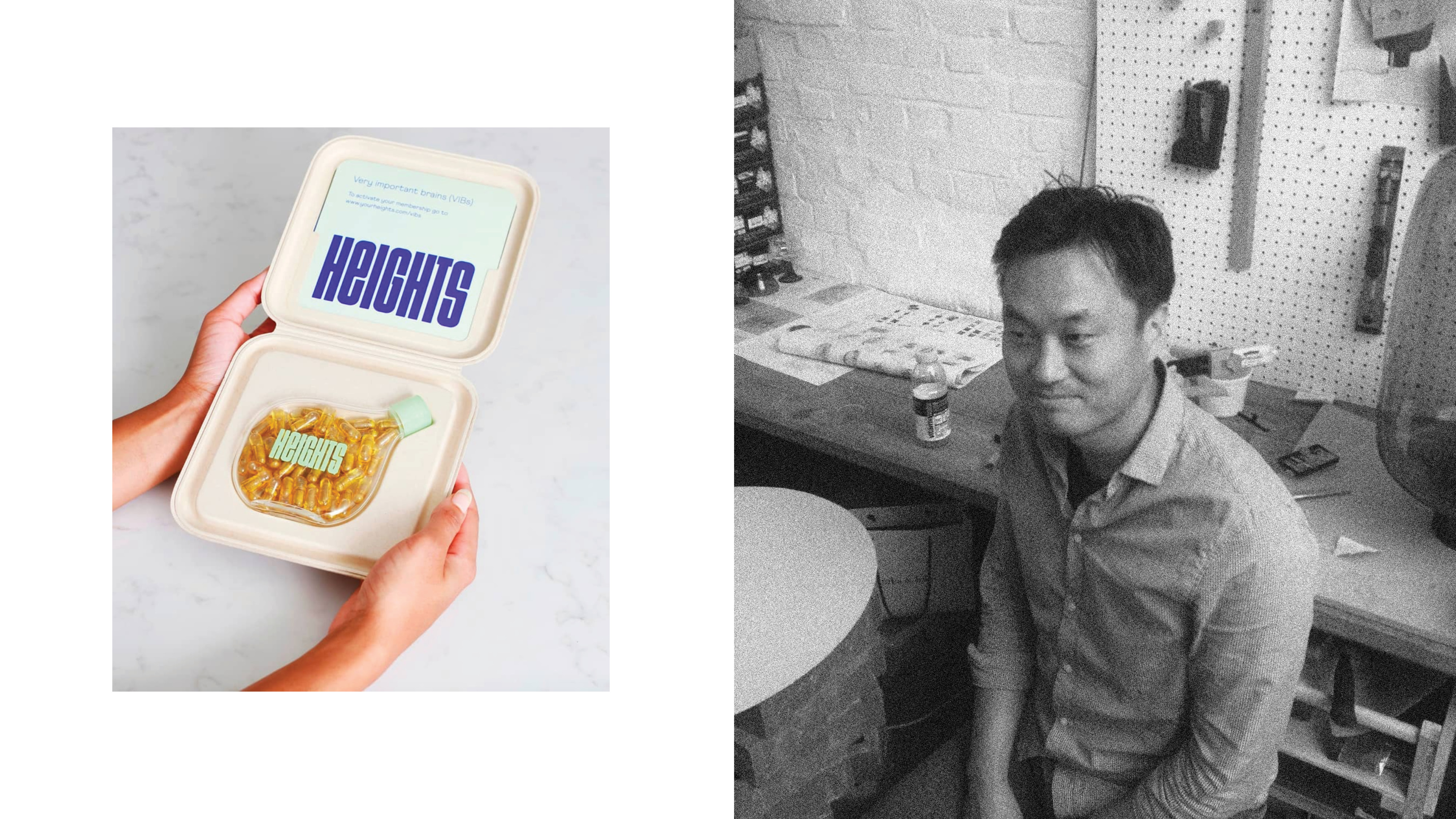

Led by Korean design mentors Seongyong Lee and Jangsub Lee, who have both been deeply involved in sustainable efforts in their own works, CITEM’s three-month intensive mentorship program includes lecture sessions, hands-on activities, as well as tasks and assignments that help further the participating companies’ knowhow on branding communication, material innovation, and design planning.

“It’s been exciting to talk to them,” say the mentors, who contributed to the selection of brands from a list of more than 200 Philippine companies. “We were already surprised when we saw their portfolio before commencing the session. We don’t think they need to create new content for their branding, however, it should be more classified and discussed internally [for it] to have better communication with potential customers outside the Philippines.”

CITEM’s sustainability program has four objectives: 1) to introduce innovative design processes and create a plan for eco-friendly life cycles for their products; 2) to build processes and ecosystems founded on solution-driven approaches to product development; 3) to develop plans toward prolonging the products’ life cycle with a process of innovation; and lastly, 4) to trailblaze process innovations that will further lead to material research and engineering, innovation, and awareness that will develop results that are at par with the latest international market trends and demands.

“Even though we have been deeply impressed by their contents [products, marketing collateral, and the like] and their own policies in terms of social value, we feel they need to have a more logical process on branding and product development,” the mentors add.

Hand in hand with the development of an improved and more eco-conscious production process for the participating brands, the mentors stress the importance of being able to communicate the value of this to its market.

“Telling the real story [of their products’ value and the processes behind it] in a more appropriate way, especially with branding and design language in terms of sustainability, would be very important to introduce themselves into the international market,” the mentors point out.

“We don’t think there is only one manual which works for everything. The main point would be that we guide them to let them develop their own progress. Phase 1 [which is branding-focused] is to find the right place for their brand and products so that they can have a proper foundation construction before extending to phase 2 [on material innovation] and phase 3 [on product design].”

In this Creative Dialogue with TouchPoint, the mentors talk about their own design journeys, overcoming challenges and realizing best practices, and how they intend to continue their eco-conscious initiatives in their own works and the sustainability program with local brands.

SEONGYONG LEE

How did your journey into the design industry start? Has it always been your interest?

No and yes. I had no idea about what design really is. I was dreaming that I might become an inventor without knowing how to be [one]. I first entered into a college majoring in physics, then I got some information about design which, for me, back then was not quite clear [what it was all about], but something that looks interesting.

Who and what were your early influences?

Tadao Ando [a contemporary Japanese architect and recipient of the Pritzker Architecture Prize]. My first trip abroad was to visit his buildings around Japan. It’s always inspiring to be touched by space plans until now.

You mention in previous interviews that you prefer your works to be “thoroughly considered, outwardly simple, good to look at, and intuitive to use.” What led you to this design principle?

I realize more and more that I prefer that an object doesn’t tell too many things. So, I, as a designer, try not to [exceed what I should put into the design]. I can say that I am sort of an anti-story teller, if I exaggerate myself.

You also talk about your interest in the marriage of industrial production and craft. How does your interest in combining both manifest in your works?

I am into both areas. Literally, I want to walk on the borderline of both. It is more related to the personal interests that I am comfortable with—I love the personality of craft and the magic of industrial production.

How would you describe your design aesthetic? What would you say is your goal as a designer?

I have to confess that I am still tuning myself for it. Since I moved back to Seoul recently, I find more room to dive [into it], in terms of flexibility and freedom.

Please tell us more about the innovative material you developed, the Plytube.

The project is about searching for the right material that people haven’t exactly found yet, even though it could be useful. The main goal that I wanted to achieve was industrializing the material. The current way of making wooden tubes demands material waste, and it is time-consuming and labor-intensive. The criteria were that it should be produced with a reasonable price, that it is strong, reliable, machine-friendly, natural, long-lasting, and beautiful, [which are also the characteristics of what I consider ‘good material’]. And the furniture that I made showed the potential of the material.

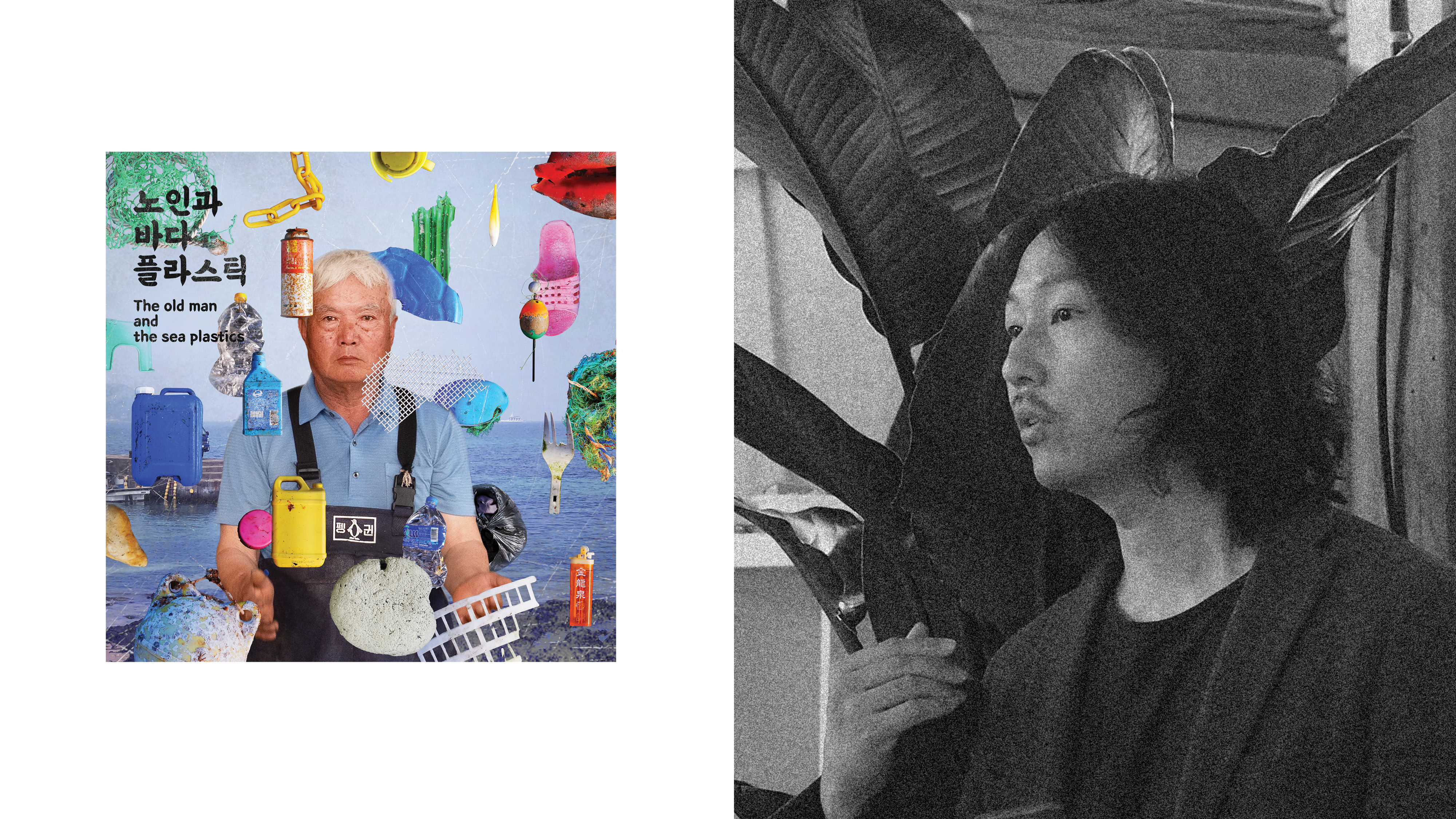

JANGSUB LEE

You are known as an eco-friendly material expert. Can you please share with us how this came about?

In 2010, I founded a design agency named Action Seoul and what we focused on at that time was branding of agricultural products and local specialties. While doing various projects related to agriculture, I naturally did a lot of research on eco-friendly design and materials. And since I started working as a professor in 2018, I began to focus more on the idea that it is essential for young designers to understand eco-friendly materials in the future.

What are your favorite eco-friendly materials and why?

It is paper. Paper is the most well-equipped material for the recycling process in Korea. More than 90% of paper is being recollected and recycled. As Korea’s recycling policy is to replace plastic with paper, we are paying more attention [to paper and its environment-friendly benefits]. In addition, in order to minimize the environmental impact when using paper, we are doing research on maintaining a good design level for brands and products while maximally reducing plastic coating, post-processing, and printing.

How would you define “sustainability”?

In product and brand design, sustainability is not only an eco-friendly concept, but [it is also about] social value and marketability. In other words, the brand internalizes sustainable social values and develops competitive designs that consider eco-friendliness in the entire process (production-distribution-consumption-disposal) to attain marketability.

What do you think makes brands and companies initially averse or resistant to the idea of shifting to more sustainable processes?

I think it's because of the cost increase. The cost of eco-friendly materials is higher, and additional costs are incurred because the existing production process [has yet to be] converted. So product innovation becomes more important. While accepting changes in materials and production methods, we have to think about design innovation that increases price competitiveness and marketability, and this is the reason why we planned this workshop [with CITEM].

How would you define “social design” and “circular design”? How do you apply these principles in your works?

Social design is a design collaboration to solve social problems, and circular design is a design that considers the entire process from production to disposal [in order] to minimize environmental impact. Our lab, DISCO [also known as the Design-Lab In Social and Circular Objectives at SNU] mainly studies these two themes, and each methodology is specified in the form of a design guide that designers can use when starting a project. We plan to make it available to the public as open source through our website.

How important are branding and communications when it comes to promoting and furthering sustainability in manufacturing and product development?

Although product innovation with a sustainable concept contains more value than existing designs, it may not be [as flashy or eye-catching] on the outside. Therefore, the role of branding to deliver such invisible value to consumers becomes more important and [should be more] advanced.

For you, what do you think are the best sustainable practices in Seoul that other cities or countries may try or adopt?

In Seoul, transparent PET bottles have been collected separately since 2020. This is because transparent PET has a higher recycling rate than other plastics and has many uses. This new policy, combined with citizens’ voluntary campaigns, is quickly being established.

In addition, companies that produce products are converting to packages that are easy to separate and collect, in response to the demands of citizens. I think this is a good practice of how both the citizens and businesses can make changes together [in accordance with] the strong will of the government.

Photos courtesy of Seongyong Lee and Jangsub Lee